Projects for the geological storage of CO2 generally plan for its injection under supercritical conditions, i.e. in a state between gas and liquid, thus maximizing the stored quantities that can involve several million tons per year. When no site is available for the secure and durable storage of CO2 near a major industrial producer, it must be transported to its injection site, entailing very high induced costs.

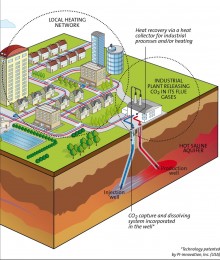

The CO2-DISSOLVED project studies a different option that consists in injecting CO2 dissolved in brine, close to the emitting source. The infrastructure for this is based on a set consisting of a production well and an injection well (click on the figure below), which allows pumping the brine from the reservoir and then re-injecting it after having been saturated in dissolved CO2. With this process, it will be possible to overcome the inherent problems of the "classic" approach, such as the pressure increase and migration of the initially present brine, or the risk that CO2 will migrate into overlying geological formations in the absence of a light gaseous or supercritical phase. In addition, it is planned to recover the heat in the brine pumped by the production well for local use by the industrial CO2 emitter and/or for feeding a heating network.

The major drawback of this approach lies in the quantity of CO2 that can be injected, which is physically limited by the solubility of CO2 in the brine. However, injection rates of around 100,000 tons of CO2 per year are a realistic target for a single doublet facility. The CO2-DISSOLVED project will thus study the technical and economic feasibility of using this technology in the immediate vicinity of low to medium industrial emitters (10,000-150,000 tons of CO2 per year) which are never considered with the supercritical injection methodology. As such, the CO2-DISSOLVED concept opens a new potential market for CCS, complementary to the classic sector which remains more appropriate for much higher tonnages of CO2 emissions.

The major drawback of this approach lies in the quantity of CO2 that can be injected, which is physically limited by the solubility of CO2 in the brine. However, injection rates of around 100,000 tons of CO2 per year are a realistic target for a single doublet facility. The CO2-DISSOLVED project will thus study the technical and economic feasibility of using this technology in the immediate vicinity of low to medium industrial emitters (10,000-150,000 tons of CO2 per year) which are never considered with the supercritical injection methodology. As such, the CO2-DISSOLVED concept opens a new potential market for CCS, complementary to the classic sector which remains more appropriate for much higher tonnages of CO2 emissions.

Dernière mise à jour le 08.08.2017